- Home

- About Us

- Services

-

- Design & Development

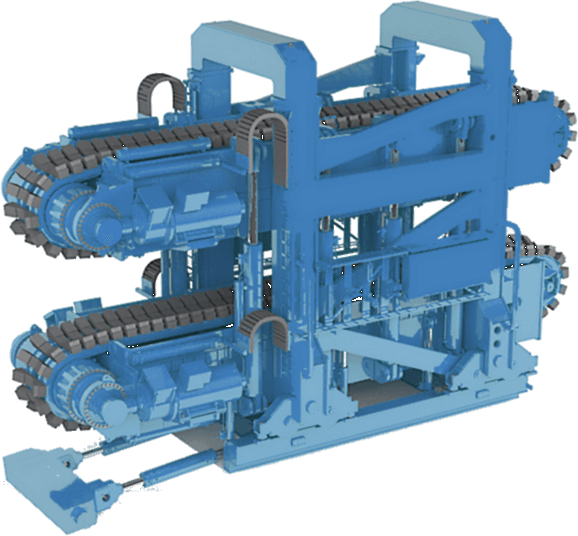

- | Product Engineering

- | Product Design

- | CAE/FEA

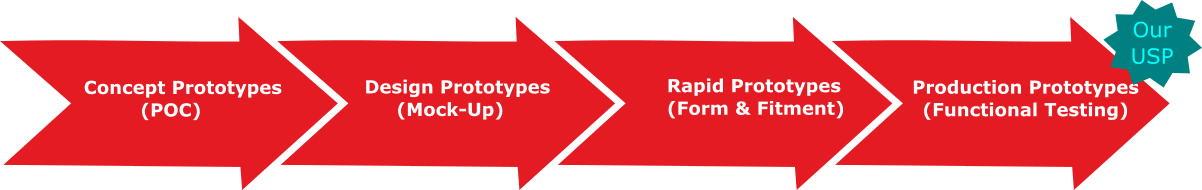

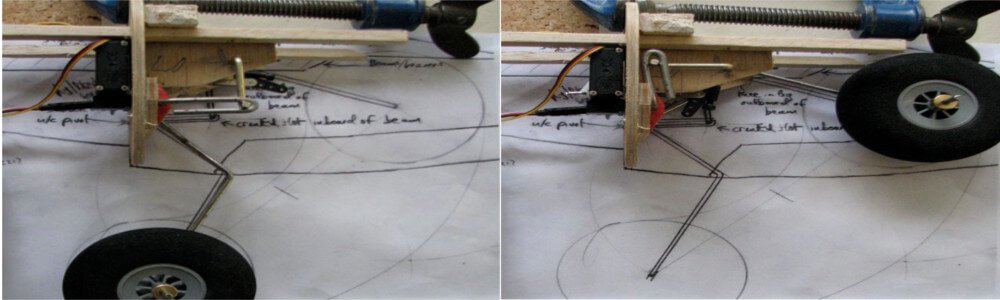

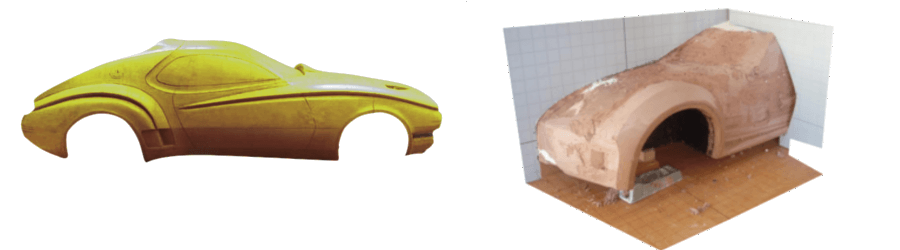

- | Prototyping

-

- Value Addition Services

- | Value-Engineering

- | Product Optimization

- | Tear-Down Analysis

- | Should Costing

-

- Software & Electronics

- | Software Support

- | Embedded System

- | System Automation

- | Web Development

-

- Solutions

- Industries

- Contact Us