Value Analysis/Value Engineering :

it is a systematic and organized procedural decision-making process. It has been used in almost

any kind of application. It helps people creatively generate alternatives to secure essential functions at the greatest worth as opposed

to costs. This is referred to as value. It is also known as Value Analysis, Value Management, Value Planning, and a host of other names.

VAVE answers 3 big questions:

What must the item do?

What does the item cost?

What is the item worth?

VA/VE evaluates your products and supply chain from a unique perspective allowing for cost reduction,

improved quality, and meaningful supplier relationships.

Different ways you can use VA/VE within your manufacturing environment

VA/VE can be applied in various ways to achieve product/process cost savings.

First decide the manufacturing area that is most critical: New Product Development or Items Currently in Production.

Next, decide if you will focus within your four walls, outside your four walls, or both.

- Internal VA/VE Focus: Improvement areas that you control

- External VA/VE Focus: Supplier development and cost reduction

- Joint Internal/External VA/VE Focus: Total value chain improvement

Steps to take when doing a VA/VE project

Below is a typical VA/VE methodology framework.

Typical Benefits of a VA/VE Project

- Reduce piece cost and total cost — up to 25% across the board savings

- Improve operational performance 20-50%

- Improve product quality between 30-50%

- Reduce the manufacturing costs up to 30%

- Improved customer-supplier relations

- Cost avoidance on future programs

- Reduction in product variations

Who Should Use Aether's VA/VE Services?

If you are not happy with the current level of profitability on your products,

or

if you are looking for an innovative way to drive cost out of your products and improve quality,

or

if you are looking to build meaningful relationships with your key suppliers,

then you should consider e-Yantrik's's Value Analysis / Value Engineering services.

Reducing product cost has taken on many different looks - six sigma, lean manufacturing, design to cost and the most common

method is to demand price reductions from suppliers. Price demands have resulted in some success but have also

resulted in strained relationships with suppliers.

And unhealthy supplier relationships will not allow you to optimize your supply chain, product quality, or

the long-term health of your company.

VA/VE is an innovative way of reducing product costs while simultaneously strengthening the

relationships with your key suppliers, and improving product quality.

Improvement occurs both internally to your organization as well as externally with your suppliers.

It's a win - win situation for all involved.

VA/VE allows you to get price reductions from your suppliers while allowing them to remain profitable.

e-Yantrik brings years of VA/VE experience to your company. We can help you change the way you approach product cost reduction,

change the way you look at your supply base, and provide valuable results.

e-Yantrik's VA/VE solutions look at your products and supply chain from a unique perspective

allowing for cost reduction, improved quality, and meaningful supplier relationships.

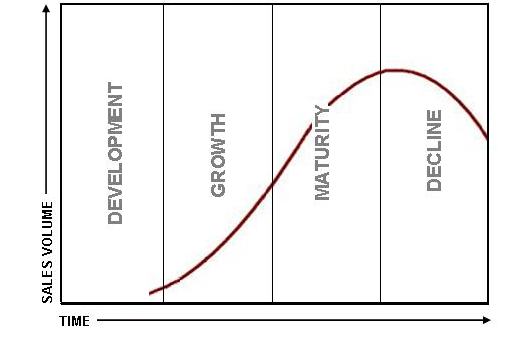

The value of the product slowly increases in development and growth stages as more features are added

and desired changes and modifications are effected.

At maturity stage the value increases to peak and

then slowly starts reduction because of competition, change of customer tastes and other factors.

The value of the product slowly increases in development and growth stages as more features are added

and desired changes and modifications are effected.

At maturity stage the value increases to peak and

then slowly starts reduction because of competition, change of customer tastes and other factors.