To maintain the profitability targets and to win the competition, it has become mandatory for all the OEMs to completely analyse all aspects of cost of the products with those of competitors to make decisions concerning products & processes.

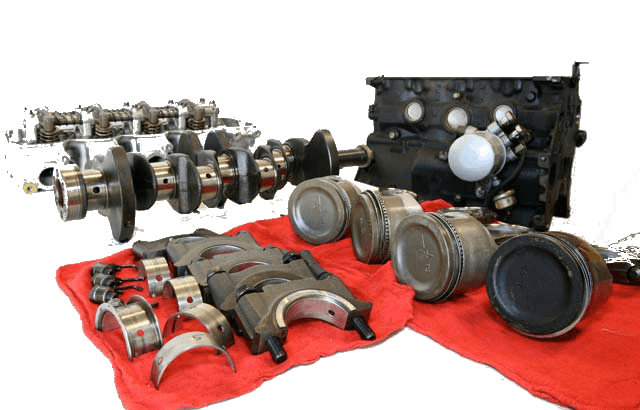

e-Yantrik's Tear-Down Analysis services comprise a systematic approach and process to compare features and performance with respect to cost. Our process is highly structured to Dismantle, Study, Analyse and Develop new options to improve.

![]()

Our vast experience in complete life cycle of product development chain (from Product design, engineering, manufacturing costing, detailed prototyping and small production run) gives us advantage to provide our customers cost effective "Tear-Down Analysis Services".

We also use our own 'manufacturing cost estimator' application for Tear-Down analysis and Should Costing of the products.

'e-Yantrik' can help to define and perform the right tear-down and technological assessments, and these can cover

the following aspects:

- Analyses of competition in the same market segment

- Benchmarking tests of complete product and components

- Benchmarking including all areas from design to product cost, performance and quality

- Key success factors analysis

- Unique selling propositions

- Analyses of strengths & weaknesses

- Performance target setting

Customer Benefits

"e-Yantrik" contributes to the Product Development with highest competence in technology and professional project management

fine tuned to the specific needs of the business. This ensures advanced technical solutions at clearly defined work split and

minimum project risk combined with best development efficiency.

- Dedicated team of high level experts

- Advanced technology solutions

- Clearly defined development time and costs

- A competent project partner

- Qualified capacity on demand

- Use of most modern development tools and methods

- Solutions are based on the wide experience available

- Absolute confidentiality